DLS 60

Impact ModifiersDescription

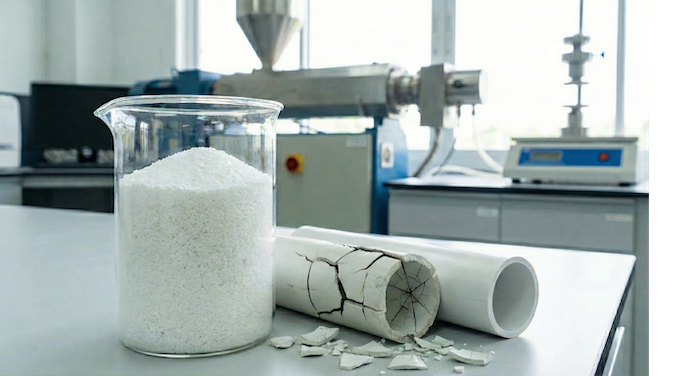

DLS 60 is engineered to deliver superior impact resistance and robust mechanical properties across a wide range of PVC applications. It ensures a consistent and homogeneous melt flow even under varying production speeds, contributing to stable processing performance. Its optimized powder morphology provides significant advantages during packaging, handling, and material transfer. Designed for efficient processing, DLS60 exhibits excellent flow characteristics, minimal dust generation, and low odor, enabling smoother, faster, and safer operation in automated loading and feeding systems. These features allow manufacturers to achieve high-quality production of complex PVC products, even under high-throughput manufacturing conditions. Offering outstanding long-term UV durability and exceptional color stability, DLS 60 ensures that PVC products retain their visual appearance and performance when exposed to prolonged outdoor weathering or harsh environmental conditions. DLS 60 can function as a standalone impact modifier within formulations; additionally, with the support of EAG Kimya's extensive expertise in PVC stabilizer technologies, producers can optimize their formulations by reducing the required dosage of the impact modifier, resulting in more cost-effective and efficient production solutions.

Applications

• PVC window, door, and technical profiles

• PVC siding and rigid sheets

• Other rigid and semi-rigid PVC applications

• Injection-molded products

• Opaque films

Technical Specifications

Type: Impact Modifier

Appearance: White powder

Particle Size: Optimized morphology

Dust Generation: Minimal

Odor: Low

Packaging: 25kg bags

Need More Information?

Our technical experts are ready to assist you with product selection and specifications.